Marshall Mix Design

- Roberts, F.L.; Kandhal, P.S.; Brown, E.R.; Lee, D.Y. and Kennedy, T.W. (1996[2]). Hot Mix Asphalt Materials, Mixture Design, and Construction. National Asphalt Pavement Association Education Foundation. Lanham, MD.

- National Asphalt Pavement Association. (1982[3]). Development of Marshall Procedures for Designing Asphalt Paving Mixtures, Information Series 84. National Asphalt Pavement Association. Lanham, MD.

- Asphalt Institute. (1997[4]). Mix Design Methods for Asphalt, 6th ed., MS-02. Asphalt Institute. Lexington, KY.

Marshall Method History

“…a simple apparatus suitable for use with the present California Bearing Ratio (CBR) equipment to design and control asphalt paving mixtures…”

- It was designed to stress the entire sample rather than just a portion of it.

- It facilitated rapid testing with minimal effort.

- It was compact, light and portable.

- It produced densities reasonably close to field densities.

Marshall Mix Design Procedure

- Aggregate selection.

- Asphalt binder selection.

- Sample preparation (including compaction).

- Stability determination using the Hveem Stabilometer.

- Density and voids calculations.

- Optimum asphalt binder content selection.

Aggregate Selection

- Determine aggregate physical properties. This consists of running various tests to determine properties such as:

- Determine other aggregate descriptive physical properties. If the aggregate is acceptable according to step #1, additional tests are run to fully characterize the aggregate. These tests determine:

- Perform blending calculations to achieve the mix design aggregate gradation. Often, aggregates from more than one source or stockpile are used to obtain the final aggregate gradation used in a mix design. Trial blends of these different gradations are usually calculated until an acceptable final mix design gradation is achieved. Typical considerations for a trial blend include:

- All gradation specifications must be met. Typical specifications will require the percent retained by weight on particular sieve sizes to be within a certain band.

- The gradation should not be too close to the FHWA’s 0.45 power maximum density curve. If it is, then the VMA is likely to be too low. Gradation should deviate from the FHWA’s 0.45 power maximum density curve, especially on the 2.36 mm (No. 8) sieve.

Asphalt Binder Evaluation

Sample Preparation

Optimum Asphalt Binder Content Estimate

Sample Asphalt Binder Contents

Compaction with the Marshall Hammer

- Sample size = 102 mm (4-inch) diameter cylinder 64 mm (2.5 inches) in height (corrections can be made for different sample heights)

- Tamper foot = Flat and circular with a diameter of 98.4 mm (3.875 inches) corresponding to an area of 76 cm2 (11.8 in2).

- Compaction pressure = Specified as a 457.2 mm (18 inches) free fall drop distance of a hammer assembly with a 4536 g (10 lb.) sliding weight.

- Number of blows = Typically 35, 50 or 75 on each side depending upon anticipated traffic loading.

- Simulation method = The tamper foot strikes the sample on the top and covers almost the entire sample top area. After a specified number of blows, the sample is turned over and the procedure repeated.

- AASHTO T 245: Resistance to Plastic Flow of Bituminous Mixtures Using the Marshall Apparatus

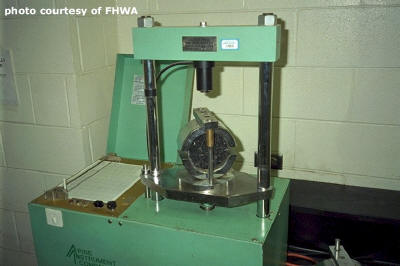

The Marshall Stability and Flow Test

| Mix Criteria | Light Traffic (< 104 ESALs) | Medium Traffic (104 – 106 ESALs) | Heavy Traffic (> 106 ESALs) | |||

| Min. | Max. | Min. | Max. | Min. | Max. | |

| Compaction (number of blows on each end of the sample) | 35 | 50 | 75 | |||

| Stability (minimum) | 2224 N (500 lbs.) | 3336 N (750 lbs.) | 6672 N (1500 lbs.) | |||

| Flow (0.25 mm (0.01 inch)) | 8 | 20 | 8 | 18 | 8 | 16 |

| Percent Air Voids | 3 | 5 | 3 | 5 | 3 | 5 |

- AASHTO T 245: Resistance to Plastic Flow of Bituminous Mixtures Using Marshall Apparatus

Density and Voids Analysis

- Bulk specific gravity (Gmb).

- Theoretical maximum specific gravity (TMD, Gmm).

- Air voids (Va), sometimes expressed as voids in the total mix (VTM)

- Voids in the mineral aggregate (VMA)

- Voids filled with asphalt (VFA)

| Nominal Maximum Particle Size | Minimum VMA (percent) | |

| (mm) | (U.S.) | |

| 63 | 2.5 inch | 11 |

| 50 | 2.0 inch | 11.5 |

| 37.5 | 1.5 inch | 12 |

| 25.0 | 1.0 inch | 13 |

| 19.0 | 0.75 inch | 14 |

| 12.5 | 0.5 inch | 15 |

| 9.5 | 0.375 inch | 16 |

| 4.75 | No. 4 sieve | 18 |

| 2.36 | No. 8 sieve | 21 |

| 1.18 | No. 16 sieve | 23.5 |

Selection of Optimum Asphalt Binder Content

- Plot the following graphs:

- Asphalt binder content vs. density. Density will generally increase with increasing asphalt content, reach a maximum, then decrease. Peak density usually occurs at a higher asphalt binder content than peak stability.

- Asphalt binder content vs. Marshall stability. This should follow one of two trends:

- * Stability increases with increasing asphalt binder content, reaches a peak, then decreases.

- * Stability decreases with increasing asphalt binder content and does not show a peak. This curve is common for some recycled HMA mixtures.

- Asphalt binder content vs. flow.

- Asphalt binder content vs. air voids. Percent air voids should decrease with increasing asphalt binder content.

- Asphalt binder content vs. VMA. Percent VMA should decrease with increasing asphalt binder content, reach a minimum, then increase.

- Asphalt binder content vs. VFA. Percent VFA increases with increasing asphalt binder content.

- Determine the asphalt binder content that corresponds to the specifications median air void content (typically this is 4 percent). This is the optimum asphalt binder content.

- Determine properties at this optimum asphalt binder content by referring to the plots. Compare each of these values against specification values and if all are within specification, then the preceding optimum asphalt binder content is satisfactory. Otherwise, if any of these properties is outside the specification range the mixture should be redesigned.

- Marshall Procedures for Design and Quality Control of Asphalt Mixtures. Asphalt Paving Technology: Proceedings, vol. 54. Association of Asphalt Paving Technologists Technical Sessions, 11-13 February 1985. San Antonio, TX. pp. 265-284.↵

- Hot Mix Asphalt Materials, Mixture Design, and Construction. National Asphalt Pavement Association Education Foundation. Lanham, MD.↵

- National Asphalt Pavement Association. (1982). Development of Marshall Procedures for Designing Asphalt Paving Mixtures, Information Series 84. National Asphalt Pavement Association. Lanham, MD.↵

- Mix Design Methods for Asphalt, 6th ed., MS-02. Asphalt Institute. Lexington, KY.↵

- Mix Design Methods for Asphalt Concrete and Other Hot-Mix Types. Manual Series No. 2 (MS-2). Asphalt Institute. Lexington, KY.↵

http://www.setestindia.com/marshall-stability-test-apparatus.html

ReplyDelete